Sequenctial Batch Reactor

A Sequential Batch Reactor (SBR) is a type of batch reactor used in wastewater treatment and chemical processes. It operates in a series of discrete batch cycles rather than continuously.

Sequential batch reactors (SBR) are reactors or basins in which the biological treatment of waste water is carried out in a series of four steps, namely filling, aeration, settling (clarification) and decanting. One of the newest solutions for treating municipal sewage is the sequential batch reactor (SBR).

PROCESS DESCRIPTION:-

Soluble and suspended Organic compounds which pollute the water are mainly Carbohydrates, Proteins and Fats, measured as BOD and COD. It is subjected to treatment via biological conversion in Aerobic phase. It is based on the fundamental theory of the activated sludge process. This treatment is also known as Aerobic suspended Growth System. While waste organic matter is aerated in an aeration basin in which micro-organism metabolize the soluble and suspended organic matter. Unlike conventional, continuous aerobic process where aerobic conversion and separation of MLSS are taking place in separate units, we propose all the activities in one unit called reactor. All the activities are happening in one reactor in sequence hence we name it Sequential Batch Reactor.

Sequential Batch Reactor Process is operated in a batch reactor mode, which eliminates all the in-efficiencies of the continuous processes. Batch reactor is a perfect reactor, which ensures highest level of treatment close to 100%.

The complete biological operation is divided into cycles. Each cycle is approx. 4 hrs (or as per Design requirement) during which all treatment steps take place.

CYCLE OF OPERATION:-

A basic cycle comprises:

- Fill-Aeration (F/A) – 4.00 hrs

- Aeration (A) – 0.5 hrs

- Settling (S) -1.0 hrs

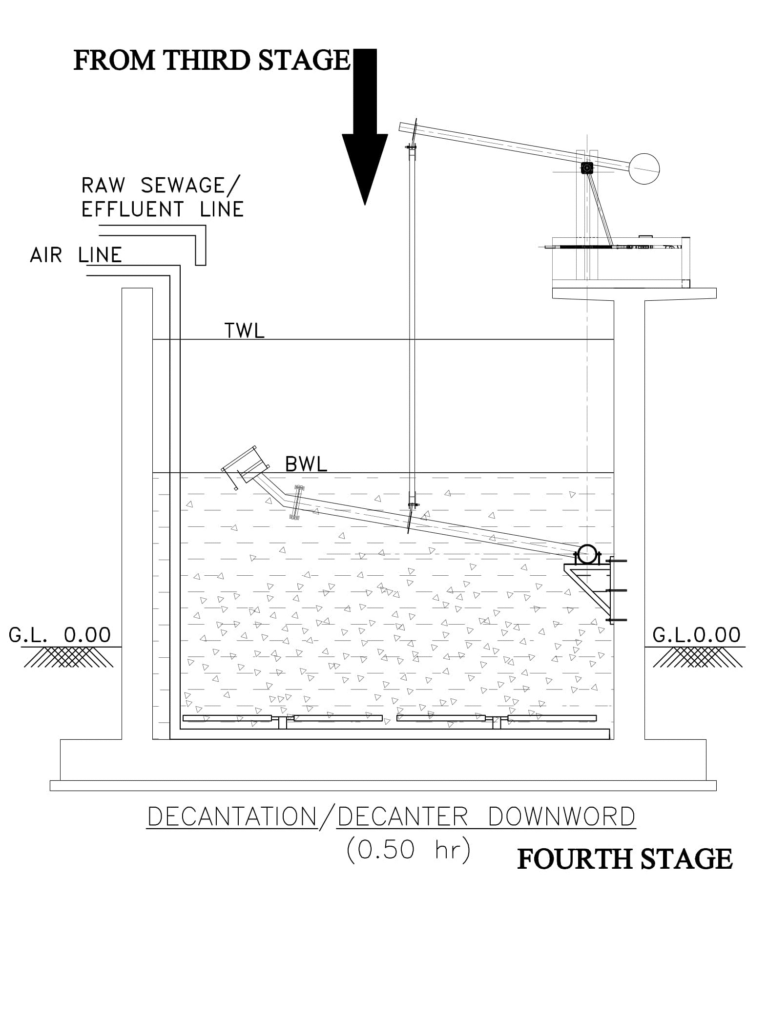

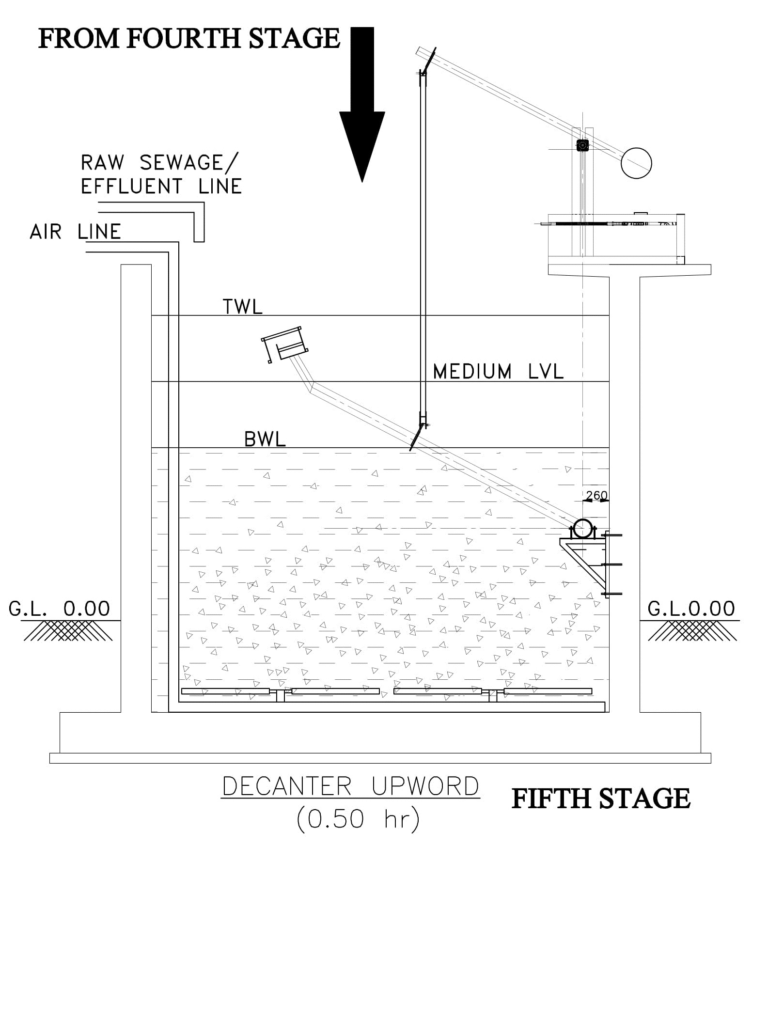

- Decanting (D) -0.5 hrs, downward, 0.5hrs upward

These phases in a sequence constitute a cycle, which are repeated after completion of cycle.

TYPICAL CYCLE:-

During the period of a cycle, the liquid is filled in the Sequential Batch Reactor up to a set operating water level and aeration of Blowers are started for aeration. After the aeration cycle, the biomass settles under perfect settling conditions. Once Settled, the supernatant is removed from the top using a mechanized arrangement working in auto mode called DECANTER. Solids are wasted from the tanks during the decanting phase.

Aerobic and facultative bacteria are the predominant micro organisms which carry out the above reaction of organic matter i.e. oxidation and synthesis; their cellular mass contains about 1% Nitrogen and 2% Phosphorous.

SILENT FEATURES:-

- Construction space requirement is very small compared to other available technology.

- High quality of treatment at very small system including Nitrogen and Phosphorus removal in single tank resulting in power saving. This process has inbuilt property of bio nutrient removal. During De nitrification process nitrogen oxide get reduce in nitrogen and phosphate get converted into low oxidation state. It finally results into recovery of oxygen. The same oxygen is utilized by MLSS for conversion of BOD into CO2 and bio mass.

- Nitrogen and Phosphorus removal efficiency is highest up to 95% because of intermediate tank operation.

3.1During Aeration and fill, substrate concentration is highest while oxygen supply is on average results in reduction in oxidized form of nitrogen and phosphate into lower oxidation state result in oxygen recovery.

R-NH2 + O2 = NOx + H2O – (During Low BOD and High DO)

NOx+ BOD =N2 + CO2+ H2O – (During high BOD and Low DO)

R-POxlow + O2 = R-POxhigh + H2O – (During Low BOD and High DO)

R-POxhigh + BOD = R-POxlow + CO2+ H2O – (During high BOD and Low DO)

- This concept has unique advantages as it utilizes maximum oxygen supplied by aeration device into bulk of liquid.

4.1 It operates at higher BOD concentration during aeration phase and results to higher substrates utilization and resulting into higher oxygen transfer.

4.2 During aeration cycle concentration of BOD decreases up to lowest level (up to 10ppm). Low concentration phase is only for short period. This results to overall higher rate of conversion in compression to other processes (conventional Aeration System

- Overall there is oxygen saving up to 30 %, equals to 30% less power consumption.

Project Sites