Moving Bed Biofilm Reactor (MBBR) Process

A Moving Bed Batch Reactor (MBBR) is a type of batch reactor designed to enhance the efficiency of chemical and biological reactions. It’s characterized by the use of a moving bed of media that supports the growth of microorganisms or catalysts.

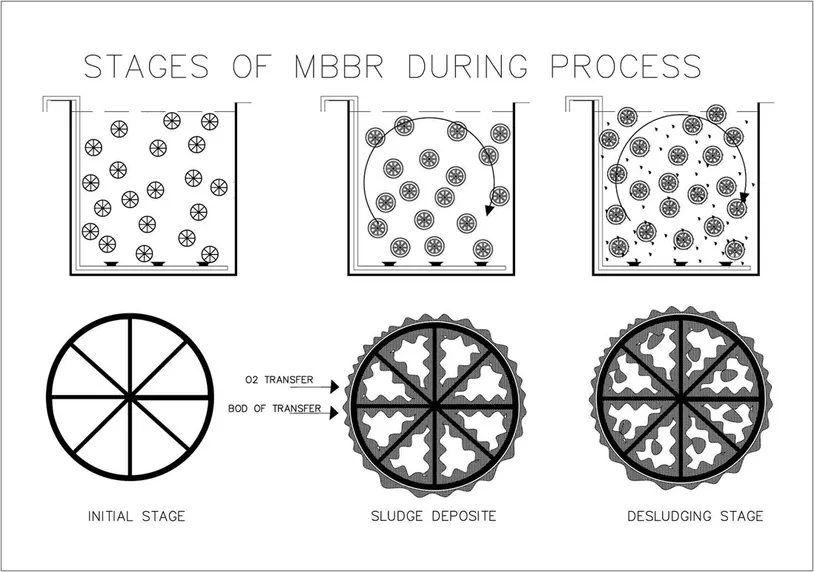

MBBR mainly is combined of two things i.e. Activated sludge process (suspended growth) and biofilter (attached growth). It uses entire tanks for biomass growth through implementation of carriers that are attached to the biofilm.

Since MBBR uses activated sludge aeration tanks, the sludge gets collected on the plastic carriers. These carriers contain a large surface area benefit of which is that it optimizes the contact of water, air, and the bacteria. The above two systems are an essential application of MBBR media. MBBR media contains two features, one is the aeration tanks and the other is special plastic carriers.

FEATURES

- Handles wide range of hydraulic, organic loads and chemical load

- Media is disigned to fludize and rotate for highest degree of mass transfer for oxygen and organic pollutants.

- It is made for random dumping with simple structural supports helps in easy installation in reactors of varied geometric shapes.

- Polypropylene, are cyclable materail of construction, has a high resistance to chemical attack and ensures longer operational life.

- Carbon black is added for providing higher abrassion resistance and UV resistance

- cylindrical shape provides structural stability

Project Sites